| Morris Mini 1000 |

I bought it for £165 from a chap at Sandiway. Margaret and I were engaged and saving hard for our wedding and a deposit on a house so this was an expense that we could have done without. Fortunately my dad came to the rescue and said he’d buy the car for us.

As for the Mini, it was an absolute revelation. By 1974, when we bought it, the Mini was a real fashion icon, a symbol of the ‘60s, but it was also really well designed and, to me, it felt revolutionary.

There was a transverse engine, with the gearbox mounted underneath the engine block and sharing the engine oil. The radiator was in the nearside wheelarch, it was front-wheel drive, had independent hydraulic suspension and the body was a monocoque, so that there was no separate chassis (with bodywork mounted on top, the bodyshell was stiff and strong enough to carry passengers, with the engine and gearbox mounted in a subframe bolted into the bodywork and the rear suspension carried in another subframe. The battery was in the boot. Suspension in early models was rubber blocks, but mine used hydarulic rams with an air reservoir on each unit. The air compressing in the reservoir created the spring and you had to pump up the suspension periodically as the suspension would settle and get lower and lower.

After the slow Ford Pop and the utilitarian Bedford van, the Mini was fantastic. It handled beautifully, the engine revved willingly and it would corner like no other car I’d driven, even on crossply tyres. When I replaced them with radials, it was even better. Ours was the 1000cc model (there was also an 850cc and a 1075cc Cooper) and had about 38bhp. It was good for around 70mph.

Best of all, the headlights were fantastic. For the first time, I really could see where I was going at night. The Mini was the first car Margaret and I owned together. I must have bought it when I was 20 and we had it for about three years.

It was mid blue with light blue-grey trim and only a few rust bubbles outside, which I rubbed down and touched up with brush paint. This time I bought the proper matching colour and acrylic paint - no more purple household paint. The bodyshell on Minis was prone to rot on the inner sill below the driver and passenger door and mine was doing that. There were some big bubbles where the rust was eating its way through from inside the box section and there wasn’t a lot you could do to stop it. The box section sills were one of the main load-bearing components of the bodyshell and so corrosion here would eventually lead to the car being scrapped as it could snap in the middle.

Rust on cars in the ‘70s and ‘80s was a major preoccupation and the cause of most cars being scrapped. Manufacturers did little to protect their cars and people used to take their own precautions and repairs. I used to jack the car up and brush used engine oil underneath, I also had some thick vinyl tape (called Protectatape) which was super sticky and would adhere to the inside of wheel-arches or the bottom of sills to protect from stone chips. There were also cans of foam filling that you could use to fill up box members on the bodyshell - you’d drill a hole in the side, put a tube on and keep pumping the stuff in until it came back out of the hole. It then hardened like cavity wall insulation in your house.If you bought a new car, you could pay extra and get it undersealed (which basically was a bitumen coating sprayed to the underside of the car. This would help, but if the surface was broken by a stone chip or scuff, water would get inside the sealant and it could make things worse. Much later, companies would offer something called Waxoyl, which would not only be sprayed underneath, but also inside box sections. If done from new, that was quite effective.

There were some horrendous bodges keeping cars together (and I'd used a fair bit of glass fibre myself), but the worst I ever saw was a Ford Cortina Mk I owned by a photographer on the Northwich Guardian called Ken. He was a terrible photographer and his car maintenance skills were clearly no better than his flat, out-of-focus pictures. Ford used a contraption called the McPherson strut which held the front wheel on. Basically, it was a lower wishbone, to which the wheel was attached, and a strut which contained a coil spring and damper. The strut was fixed to the wishbone at the bottom and then at the top to the bodyshell of the car inside the wheelarch. It was simple, cheap and effective, but the trouble was that the top fixing on the bodyshell would corrode and the strut could push through and collapse. Both struts on Ken's Cortina had gone and the suspension was in danger of collapsing inwards on itself. To solve the problem, Ken had jacked up the car and fixed a piece of 3x2 timber across the engine bay from strut top to strut top. This was all that was preventing the front of the car sitting cross-legged on the tarmac. Ken drove around like that for a few months until his wife's parents, fearful for the safety of their grandchildren perhaps, loaned him the cash to buy a new VW Beetle.

The Mini was amazing after my previous cars, but it was a utilitarian car, built to a tight budget. The bodyshell had exposed external seams, so across the front A-pillar and down the rear C-pillar, the body parts were welded together along a seam which stuck out from the bodyshell. Hinges for doors and the boot were external and the windows were sliding, rather than wind-up/down. This meant that the space within the doors, which would hold the winding mechanism and where the glass would retract, could be used. Space was at a premium in the Mini, so the door space was used for two massive bins, which would hold lots of stuff. Door handles in early models consisted of a wire drawn across the door, which you pulled to open the catch. My car, being a little later, had a small lever near the lock. There was a leather strap which stopped the door opening too wide.

There were some design flaws on the Mini. The distributor cap was right at the front of the car and was vulnerable to wet. A well-known problem was the engine dying if you drove through a large puddle. Another was more serious - a lot of Minis caught fire in crashes. If the car turned on its side, the filler cap for the petrol tank, which stood proud rather than flush to the bodywork, would be ripped off, allowing fuel to spill. If the car was scraping down the road on its side, there would be sparks everywhere, so a fire was inevitable.

Inside, the only instruments were held in one unit in the centre of the dashboard and comprised a large speedometer with a number of warning lights set within the speedo. There was a temperature gauge at one side and an ammeter at the other. There was a storage shelf across the dashboard and small storage bins at the side of the rear seats. The steering wheel was massive and set close to the horizontal (like a bus driver), while the gear lever must have been four feet long, disappearing under the dashboard where the gearbox was sited.

You could get four people in the Mini (and we often did), there were seat belts in the front, but none in the rear.

We both loved the car and it served us well. We did have a few problems with it - the SU carburettor needed its oil damper filling every couple of weeks and the cylinder-head gasket failed. My friend, John Quigley fixed that for me one night. Our longest trip was from Northwich to Birmingham for Margaret’s brother’s wedding (Graham and Lynne). We took Harvey and Kath (who was heavily pregnant with Louise), so this was a real test for the Mini. Three six-footers and a heavily pregnant woman. It was fine, except that (on the way back) the car started to overheat as the fan belt was slipping. Because the radiator was at the side of the car and out of the airflow, if the mechanical fan wasn’t turning, the engine would overheat. We managed to stop the engine boiling over by backing off to 50mph and turning the heater up to full belt. It was a warm day, so we had to have all the windows open. It must have been a pretty uncomfortable journey for Kath!

The Mini was sold when it became more and more expensive to repair. Final straw was the need for a new steering rack which would have cost more than the car was worth. We sold it for the best price we could and I bought car No 4 - a Vauxhall Viva HC.

|

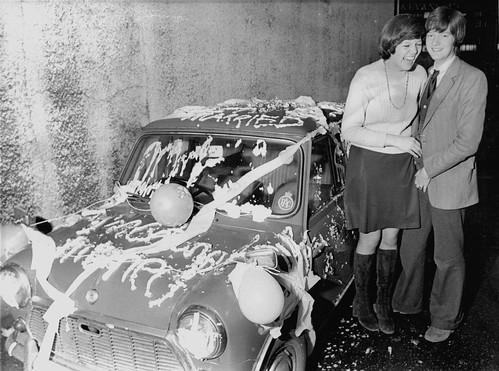

| Our Mini decorated by workmates before our wedding in 1974 |

Going from a Bedford HA to a Mini is an interesting transition. You basically summarized the Mini here; they are definitely the must-have car of the sixties. Despite it appearing revolutionary, it’s still economical enough for daily use. And wow, I have to say I’m impressed that you remember almost every detail of this Mini’s issues! Now that I think of it, this could be a great restoration project. :)

ReplyDeleteNicole, I wish I still had the car, but then I wish I still had almost every car I ever owned (except the Bedford HA van).

Delete